SAP Business One ERP for Pharma Industry

The global pharmaceutical industry has seen significant advancement in the past few years and is emerging as one of the largest sectors of the healthcare economy.

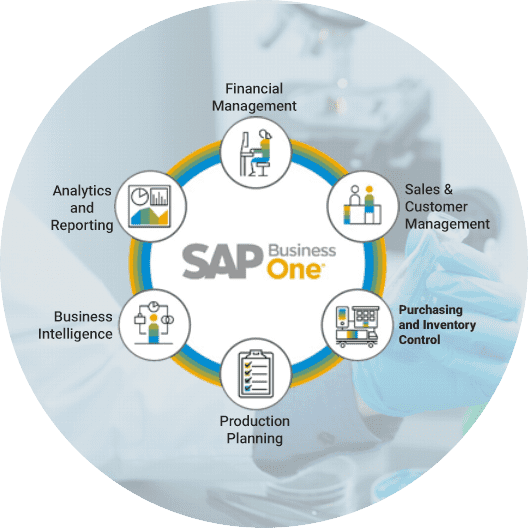

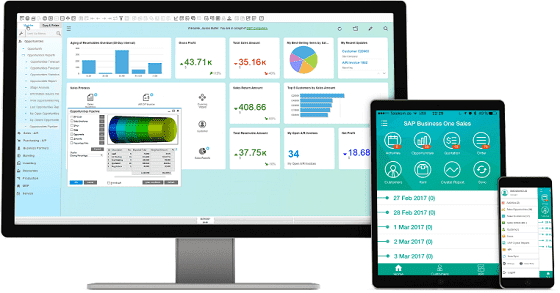

Leading healthcare and pharmaceutical industries are adopting SAP Business One to improve the efficiency of business operations, increase the productivity of the employees and to respond easily to market demands.

The pharmaceutical industry is a complex and demanding one. Companies need to be able to manage their inventory efficiently, control their costs, and provide excellent customer service. SAP Business One is an ERP software that can help pharma companies do all of this and more.

Here are just a few of the benefits of using SAP Business One in the pharma industry: