How SAP Business One ERP Empowers Plastics and Injection Moulding Companies

How SAP Business One ERP Empowers Plastics and Injection Moulding Companies

In the dynamic world of plastics and injection moulding, staying competitive requires efficiency, adaptability, and a keen eye for cost control. Managing complex production processes, diverse materials, and fluctuating customer demands can be a daunting task. Enter SAP Business One, a powerful ERP solution specifically designed to empower small and medium-sized businesses (SMBs) in the plastics and injection moulding industry.

A Single Source of Truth for Streamlined Operations:

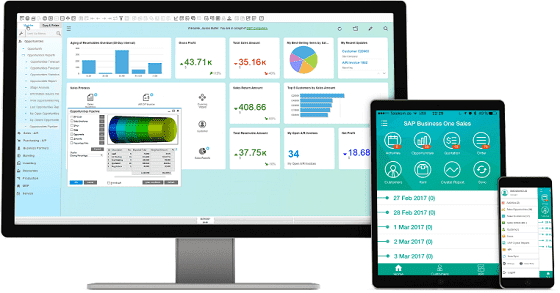

Imagine eliminating data silos and manual processes, gaining real-time visibility across your entire operation, and making informed decisions based on accurate data. That’s the transformative power of SAP Business One. This integrated ERP system centralizes all your critical business information – from inventory management and production scheduling to sales and customer relationship management (CRM).

Benefits Tailored for Plastics and Injection Moulding:

Optimized Inventory Management: Gain real-time inventory visibility, track raw materials, finished goods, and work-in-progress across multiple locations. Manage complex lot sizes, expiry dates, and specific material properties like color and grade. Reduce waste and optimize purchasing with accurate material demand forecasting.

Efficient Production Scheduling and Control: Schedule production runs based on machine capacity, material availability, and customer orders. Track work orders through each stage, identify bottlenecks, and optimize resource utilization. Manage tool and mold maintenance schedules to ensure on-time deliveries and minimize downtime.

Enhanced Quality Control: Integrate quality control checks into the production process to ensure product consistency and compliance with industry standards. Track defects, identify root causes, and implement corrective actions.

Cost Control and Profitability: Monitor production costs in real-time, identify areas for improvement, and set precise cost targets. Analyze profitability by product, customer, or project to inform strategic decision-making.

Streamlined Sales and Customer Management: Capture customer orders, manage quotes, and track deliveries seamlessly. Provide accurate lead times and proactive communication to enhance customer satisfaction. Gain insights into customer buying patterns and preferences to personalize offerings and boost sales.

Additional Advantages for Plastics and Injection Moulding Companies

Industry-Specific Add-ons: Enhance the core functionalities of SAP Business One with industry-specific add-ons like moldflow simulation, nesting software, and material data management solutions.

Scalability and Flexibility: As your business grows, SAP Business One scales with you. Add new modules, users, and functionality as your needs evolve.

Mobile Access: Access critical business data and workflows anytime, anywhere, through mobile apps. Enhance collaboration and decision-making on the go.

Improved Collaboration: Break down departmental silos and foster real-time collaboration across sales, production, inventory, and finance teams.

Real-World Success Stories

Numerous plastics and injection moulding companies worldwide have harnessed the power of SAP Business One to achieve remarkable results. A leading manufacturer of plastic packaging solutions experienced a 20% reduction in lead times and a 15% increase in production efficiency after implementing SAP Business One. Similarly, a custom injection molding company saw a 30% improvement in on-time delivery rates and a 10% decrease in inventory costs.

Investing in Your Future

Choosing the right ERP solution is a critical decision for any business. But for plastics and injection moulding companies, SAP Business One offers a compelling combination of industry-specific functionalities, affordability, and scalability. With its powerful tools and integrated platform, SAP Business One empowers you to streamline operations, optimize costs, and achieve sustainable growth in today’s competitive landscape.

Ready to take the next step?

If you’re a plastics or injection moulding company looking to elevate your business to new heights, consider SAP Business One. Contact a certified SAP partner today to learn more about how this powerful ERP solution can help you shape your success.